Author: Mr. Harshal Trivedi, Mr.Rohan Mishra

The current decade is of Automation and Innovation. Intelligent Solutions and Analytical Platforms are contributing to almost every sector. Artificial Intelligence is not a Black-box anymore. There’s no denial of the fact that Industry 4.0 is the digital transformation of manufacturing and its primary related industries. It’s all about an innovatively different, smarter, and better approach to every step of the chain process, starting from production and ideation to respective portions, and also supplies chain inventory management, and more. Enabling machines in manufacturing units to perceive information from the physical world and assist resources in complex processes opens the door for many potential opportunities.

The important part of Vision Intelligence which is computer vision is already having an unexceptional contribution to the most important sector i.e. manufacturing industry. The primary goal is to create a ‘smart approach’ that is capable to see, interact, and do the same work as humans do manually but with greater precision and with accurate results. When we speak for quantitative functions and its outcome, nothing can match the rapidness, accuracy, & precision of Video Analytics Solutions. Vision Intelligence system that involves Computer Vision comprises high-resolution surveillance cameras, optics, and AI integration to provide several benefits to large manufacturing units plus its secondary warehouse & Logistics too.

For Instance, Imagine how much time & Resources manual inspection can take while inspecting the complex machine parts on the assembly lines with a naked-human eye. And in 2022, modern-automated Video Intelligence systems are no longer bound to structural and repetitive task limitations.

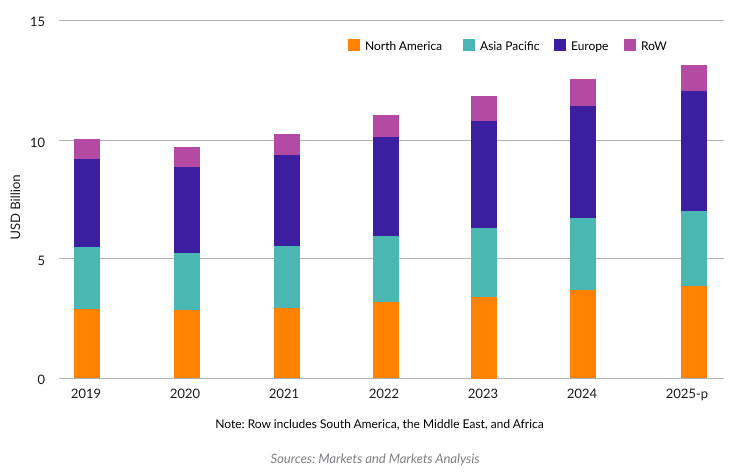

Industry 4.0 has benefited from Computer Vision even more in an era of pandemics, as it is mostly used for inventory purposes and assembly lines in post-production. In the past decade (2018), the market for computer vision globally stood at over $9.2 B, and now the data shows that it is expected to surpass $13.0B by 2025 in the present decade. Talking about continents, then both Europe and North America are front-runners in the adoption of the Computer Vision pipeline in manufacturing and its primary industries.

As per New research from Insight and IDG shows that 37% of modern-manufacturing enterprises have definite plans to involve and 44% report they are investigating the technology to implement.

TUSKER Vision Intelligences promotes and focuses on a Secured & Resilient Video Analytics Solution. We are here to empower any manufacturing use-case irrespective of image-video data density and Accelerate & Automate within a fraction of time.

And this SAAS offering relieves the current manufacturing enterprises from the conventional approach & doing all the legacy operations, but instead, we are allowing them to drive their image-video data by choosing their own VIDEO-INTELLIGENT PLATFORM and it’s all with only 3 clicks i.e. UPLOAD| TRAIN | DEPLOY.

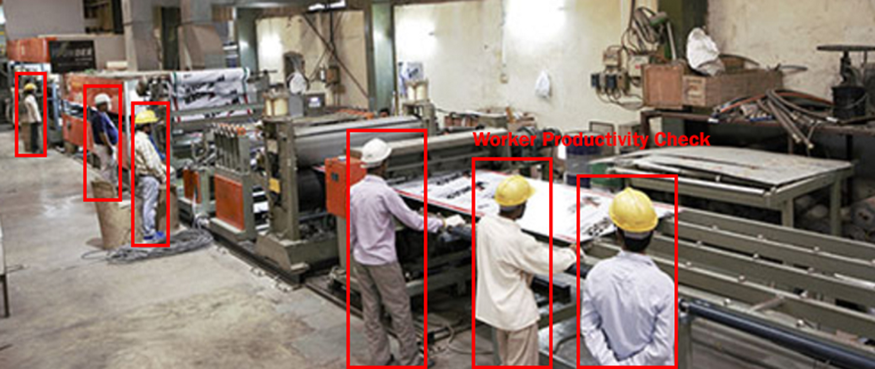

(Image: For Referential Understanding only)

Image Context: TUSKER with NO-CODE AI Platform blends Vision Intelligence which unlocks new intelligence and drives outcomes at scale

(Image: Above attached visual is for referential understanding only)

(Image: Above attached visual is for referential understanding only)

(Image: Above attached visual is for referential understanding only)

A. VALVE: PROPER OPEN/CLOSE | KNOB: OPEN & CLOSE

B. Capturing Surprise breakdowns and halting production when equipment falters.

Note: We have many more use cases. Contact Team TUSKER to know more.

If you have more queries or questions about computer vision in manufacturing or want to have a DEMO or need a CV-based solution, contact our TUSKER AI experts today! Want to know more about Buzz in our world of TUSKER NO CODE AI, feel free to contact us.

Talk to our founder, and strategist Harshal and Learn more from our Real-time use cases.

Content Contribution: Rohan Mishra, Analyst at TUSKER AI